Robotics Interoperability: The Solution to Communication Issues in Diverse Robot Fleets

In our latest report “Robotics Interoperability: A solution to the communication issues of diverse mobile robot fleets”, we dive into the robotics market, discuss how the diversification of robotic fleets is creating several pain points across the industry, and how there is a need for a universal solution to these interoperability issues.

With the global robotics market projected to reach €175.8B by 2025, growing at a 26% Compound Annual Growth Rate (CAGR), it does not come as a surprise that the robotics industry is booming, creating many new opportunities and challenges.

As a result of this growing demand for robots, warehouses all around the world are becoming more interested in automation. In fact, the value of the warehouse automation market is estimated to increase to €25B in 2026 at a 10.41% CAGR during the forecast period — that’s twice as much as back in 2019.

Interoperability Pain Points in the Robotics Industry

Even though the term interoperability has been known in the industry for a while, the adoption of the practice is hardly anywhere to be seen. However, there are two main factors driving the need for interoperability in the robotics industry: the growing demand for mobile robots and the diversification of robotic fleets. Many warehouses, logistic centres, hospitals and factories around the world are deploying robots that are often supplied by different manufacturers.

“Do you want to know more about the different types of robots and robotic technologies that are on the market today? Check out the first part of our robot guide!

Robotics 101: A Complete Guide to Warehouse Robots by Application”

In fact, it is estimated that the mobile robots market will grow from €15.7B in 2018 to € 45.4B by 2023, following an immense growth of 23.71% CAGR during the forecast period. It is even estimated that there will be around 50K robotic warehouses around the world by 2025 — up from only 4K in 2018. As a result, many industries will see new levels of automation.

With this diversification of robotic fleets, the industry needs to become more aware of the communication problems that a lack of robotics interoperability can cause. Besides, with robots becoming more autonomous, it is important that they begin to communicate effectively. The lack of robotics interoperability can, among others, lead to delays in operations, collisions, and serious accidents on the work floor.

Aaron Prather, Senior Technical Advisor at FedEx Express

Aaron Prather, Senior Technical Advisor at FedEx, emphasises that “interoperability is going to be key if we are going to see major roll outs of robotics in both industrial and public spaces. We are going to have some robots that will be working on the same mission together, while others will be doing other tasks, but still having to operate in the same shared space. If we don't have some degree of Interoperability to allow robots to communicate with each other their intent and mission, they will fail. Either by not doing their mission as intended or not in a safe manner. This latter point is very critical if humans may also be in the same shared space.”

“We talk a lot about interoperability at Meili Robots, and we sure do understand that things can get complicated very easily when addressing the issues that arise due to a lack of interoperability.

To guide you through the complex world of robotics interoperability, we have created an in-depth industry report. Here, you can find all the answers to your interoperability questions (and much more!).

Download our report on Robotics Interoperability here!”

Technological Drivers for Robotics Interoperability

The ongoing implementation of robots and automation solutions across the industry also comes with an extended focus on various technologies that will continue to be drivers for market growth and indirectly make companies more aware of the need for robotics interoperability. These include artificial intelligence, the Internet of Things (IoT), B2B cloud integration solutions, machine learning, Industry 4.0, enterprise resource planning (ERP), and many more.

Considering the wide range of benefits these technologies bring to the market, it is no surprise that we are expected to see tremendous growth — especially in the supply chain market. The latter is estimated to grow at a 39.4% CAGR and reach €18B by 2027.

The fact that interoperability is an absolute necessity for multi-diverse systems to operate, makes it one of the most important aspects of today’s IT world. In fact, we can see many companies in warehousing and manufacturing starting to implement ERP technologies that help them automate their operational processes via a single system.

“Are you looking for ways to automate your warehouse but you do not really know where to start? In that case, I would highly recommend you to give the second part of our robot guide series a read:

Robotics 102: A Complete Guide to Warehouse Automation”

In addition, IIoT technologies and robotics interoperability go somewhat hand in hand as the IIoT lets companies establish a communication network between their different devices, which in turn provides them with detailed, timely data about their production and overall operations.

An Urgent Need for Universal Connectivity

Besides the increasing adoption of robots, advances in robotics technology are bringing about a variety of operational changes in warehouses, logistic centres, and factories. However, as robot manufacturers do not have the resources to keep up with such developments, this only increases the need for interoperability in the robotics industry.

Universal connectivity relates to the ability of new technologies to connect with any system or device. This vision is becoming increasingly important, especially if the robotics market continues to grow at its current speed. The Robot Operating Software (ROS) is a great example of this as it has allowed mobile robots to develop more quickly. A universal fleet management system like Meili FMS can similarly contribute to the acceleration of robotics interoperability in diverse fleets.

Jim Beretta, the Robot Industry Podcast

Jim Beretta from the Robot Industry Podcast adds to this that “we are now witnessing companies producing bolt-on technologies to make all robot applications collaborative, aware and smart”.

Evidently, technological advances are closely related to automation and the diversification of mobile robot fleets. AI is expected to advance robot capabilities during 2021, allowing robots to seamlessly adapt to different environments and carry out new tasks. This improves the robots’ level of communication as well, which will not only help them carry out more complex tasks, but it will also be a huge help in terms of robotics interoperability.

Further Insights into Robotics Interoperability

Robotics interoperability is without a doubt one of the main drivers for robotic development and market growth. However, if neglected, it may stand in the way of this growth. To avoid this from happening, we continuously strive to raise awareness around the lack of robotics interoperability.

We have therefore created a detailed industry report on the topic, which dives deeper into the technologies mentioned above as well as other trends that are reshaping the market. We also talk about the ways in which robot fleets are diversifying and becoming more autonomous while continuously reflecting on the ways in which robotics interoperability relates to all of these factors.

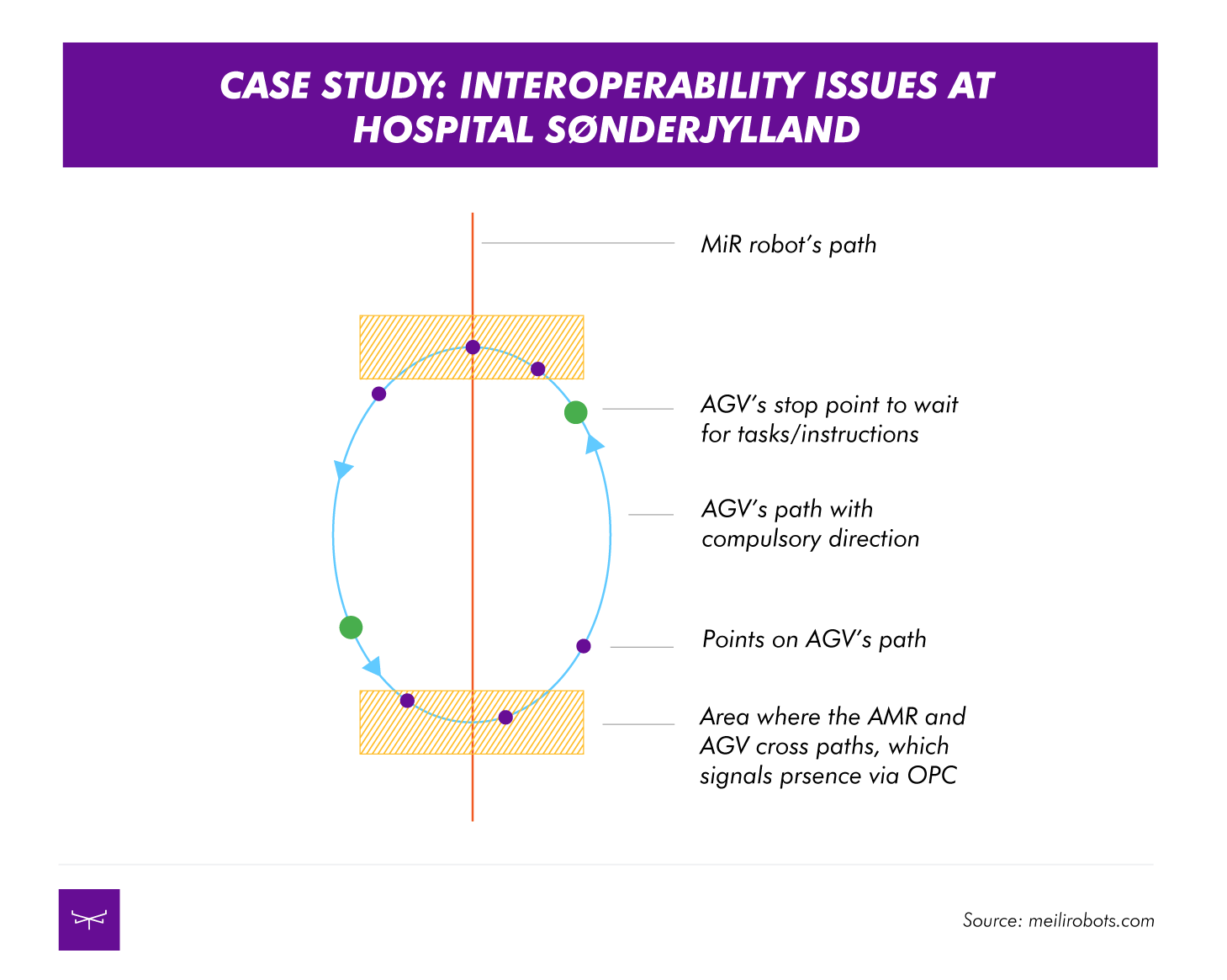

Case Study: Managing Diverse Robot Fleets at a Danish Hospital

The report also includes a case study about the Management of Robotised Transport project — better known as project START (Styring Af Robotiseret Transport), which was conducted at Hospital Sønderjylland in Denmark. The project tested, adjusted, and customised MiR’s fleet management system in a setting with different types of mobile robots and, of course, the hospital logistics.

None of the participating project partners were surprised by the outcome of the study: evidently, a universal fleet management system is needed to provide an overview of the entire fleet, regardless of robot types or brands. Moreover, it is of great importance to enable full control of the routes, locations, tasks, and speed of the robots to minimise work floor accidents and simultaneously optimise the overall efficiency of the operations.

The Development of Interoperability Standards

The case study also discusses the development of interoperability protocols and standards — with the robotic being used at Hospital Sønderjylland operating on the VDA 5050. There are several countries that have been working on the development of interoperability standards — i.e. the German VDA 5050 and Version 1.0 of the MassRobotics Interoperability Standard.

However, the VDA 5050 primarily focuses on AGV standards and the MassRobotics Interoperability Standard focuses on the transmission of basic robot-to-robot information. This means that there still is a strong need for a common interface with task management and fleet allocation features that control any type or brand of robots.

Our aim is to tackle the lack of robotics interoperability by offering an interfleet solution that removes the barriers between different types and brands of robots. If you are interested to know more about our product, you can find all the details on our website. And if you have any further questions, please feel free to contact us at any time. We are always happy to help.

About Meili Robots

Meili Robots is developing the next-generation of mobile robots fleet management, called Meili FMS. A universal digital solution, an all-in-one platform that is capable of handling different kinds of Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs). Enable traffic control, empower interoperability and facilitate automated task allocation — all via intuitive UI. Check our website meilirobots.com/product to learn about our products. Contact us to find out more: info@meilirobots.com.

![[Report] Interfleet Software Integration](https://images.squarespace-cdn.com/content/v1/6616ae8561bf6a6177fc5d75/1712762524630-UZGSXF36N80HMNXAB7HP/undraw_version_control_re_mg66.png)

![[Checklist] 2021 Holiday Prep: A Checklist for Online Retailers](https://images.squarespace-cdn.com/content/v1/6616ae8561bf6a6177fc5d75/1712762524813-461RNWV3VS97G57AIM6G/undraw_To_do_re_jaef.png)